hunter ceiling fan instruction manual

Welcome to the Hunter Ceiling Fan Instruction Manual. This guide provides essential information for installing, operating, and maintaining your ceiling fan. Ensure safety, proper installation, and optimal performance.

Overview of the Hunter Ceiling Fan

The Hunter Ceiling Fan is a high-quality, energy-efficient solution for enhancing home comfort. Known for durability and sleek designs, Hunter fans offer superior airflow and quiet operation. With a range of styles, from traditional to modern, they suit any decor. Features include multiple speed settings, reversible motors for seasonal use, and optional lighting kits. Hunter fans are built with premium materials, ensuring long-lasting performance and minimal maintenance. Their innovative designs, such as angled mounting kits, cater to diverse ceiling types. Whether for residential or commercial spaces, Hunter Ceiling Fans deliver exceptional performance, combining functionality and aesthetics to create a comfortable environment year-round.

Importance of Following the Instruction Manual

Following the Hunter Ceiling Fan instruction manual is crucial for ensuring safety, proper installation, and optimal performance. The manual provides detailed steps to avoid potential hazards, such as electrical issues or improper mounting. Adhering to the guidelines guarantees the fan operates efficiently, reducing energy consumption and extending its lifespan. Additionally, failure to follow instructions may void the warranty or lead to unsafe conditions. By carefully reading and adhering to the manual, users can enjoy reliable operation and maximize their investment. Proper installation and maintenance also prevent common issues, ensuring the fan functions as intended for years to come.

Installation Guide

This section provides a comprehensive guide for installing your Hunter Ceiling Fan. It includes safety precautions, step-by-step instructions, and tips for choosing the right location to ensure proper and efficient operation;

Safety Precautions Before Installation

Before installing your Hunter Ceiling Fan, ensure all safety precautions are followed. Turn off the power supply at the electrical panel, not just the light switch. Verify the ceiling can support the fan’s weight, typically up to 50 lbs. Use appropriate screws and hardware to secure the fan bracket to the ceiling joist. Avoid overloading the circuit, and ensure all wires are correctly connected. Wear protective gear like gloves and safety glasses; If unsure, consult a licensed electrician. Keep children and pets away from the area. Never operate the fan near water or in humid conditions without proper ratings. Follow all local electrical codes and manufacturer guidelines for a safe installation.

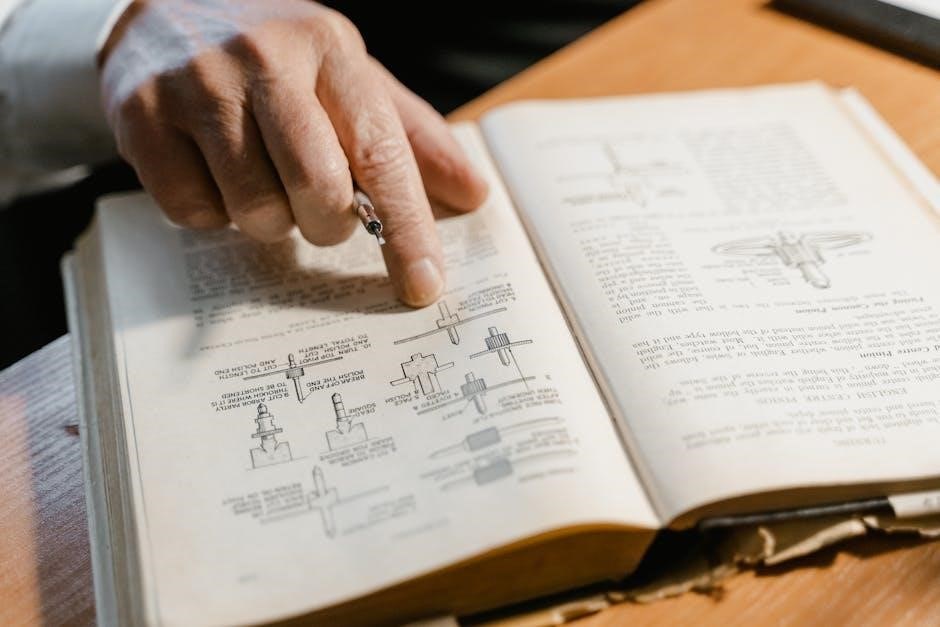

Step-by-Step Installation Process

Start by unpacking and organizing all components. Turn off the power supply at the circuit breaker. Locate the ceiling joist and install the mounting bracket using wood screws. Hang the fan motor from the bracket. Connect the fan wires to the household wires, ensuring black to black and white to white. Secure the canopy to the ceiling. Attach the fan blades and light kit (if applicable). Tighten all screws and test the fan. Ensure all connections are secure and the fan operates smoothly. Refer to the manual for specific wiring diagrams and additional guidance. Proper installation ensures safety and optimal performance.

Choosing the Right Location for Your Ceiling Fan

Selecting the ideal location for your Hunter ceiling fan ensures optimal airflow and comfort. The fan should be installed in a central position, ideally 8-10 feet above the floor for maximum circulation. Avoid placing it near corners or walls to prevent uneven air distribution. For sloped ceilings, use an angled mounting kit to secure the fan properly. Ensure the location allows at least 12 inches of clearance from any walls or obstructions. Proper placement enhances energy efficiency and provides consistent cooling or heating throughout the room. Always follow the manufacturer’s guidelines for specific installation requirements.

Operating Your Hunter Ceiling Fan

Operate your Hunter ceiling fan efficiently by adjusting speed settings and using the remote control (if applicable) for smooth, energy-efficient performance in your home or office.

Understanding Fan Speed Settings

Your Hunter ceiling fan offers multiple speed settings to customize airflow and energy efficiency. Typically, fans feature low, medium, and high speeds, allowing you to adjust based on room conditions. The pull chain or remote control (if applicable) enables easy switching between settings. Low speed provides gentle circulation, while high speed maximizes airflow for cooling. Energy-efficient designs ensure optimal performance at every setting. For seasonal use, some models include a reverse function to circulate warm air in winter. Always refer to your manual for specific speed options and troubleshooting guidance to ensure smooth operation and longevity of your fan.

Using the Remote Control (If Applicable)

If your Hunter ceiling fan comes with a remote control, it offers convenient operation from a distance. Start by inserting the provided batteries into the remote and ensure the fan receiver is properly installed. Sync the remote with your fan by following the pairing instructions in the manual. Use the remote to adjust speed settings, turn the fan on/off, or control the light kit (if equipped). For troubleshooting, check battery life, clean contacts, or reset the remote by turning off power to the fan and restarting. Always refer to the manual for specific remote functions and compatibility with your fan model to ensure smooth operation and optimal performance.

Maintenance and Troubleshooting

Regularly clean fan blades and check for loose screws to ensure smooth operation. Troubleshoot issues like dim lights or non-working remotes by checking connections and batteries. Always follow safety guidelines before performing any maintenance or repairs to avoid accidents and ensure optimal performance. Refer to the manual for detailed troubleshooting steps and solutions to common problems. Proper care extends the lifespan of your Hunter ceiling fan and maintains its efficiency and appearance over time.

Cleaning and Maintaining Your Ceiling Fan

Regularly clean your Hunter ceiling fan to ensure optimal performance and aesthetics. Use a soft, dry cloth to wipe down the blades, motor housing, and light fixtures. Avoid harsh chemicals or abrasive materials that may damage the finish. For stubborn dust, dampen the cloth slightly, but ensure no moisture seeps into electrical components. Check for loose screws and tighten them as needed. Inspect blade balances and adjust if necessary to prevent wobbling. Dust light bulbs and replace them when dim or burned out, ensuring the correct wattage is used. Clean the motor’s intake grilles with a vacuum to maintain proper airflow. Lubrication is not required for Hunter fans. Always turn off the power before performing any maintenance. Refer to the manual for specific cleaning and maintenance guidelines to keep your fan running smoothly and safely.

Troubleshooting Common Issues

If your Hunter ceiling fan encounters issues, start by checking the power source and circuit breaker. Ensure the fan is properly installed and all connections are secure. If the fan does not turn on, verify the remote control’s batteries and dip switch settings. For dimming or flickering lights, replace bulbs with the correct wattage specified in the manual. Address wobbling by tightening blade screws or adjusting the balance kit. If the fan hums or makes noise, inspect for loose parts or debris. For remote malfunctions, re-sync the remote by turning the power off and on. Consult the manual for specific troubleshooting steps for your model, and contact Hunter support if issues persist.

Replacement Parts and Upgrades

Discover how to identify and order genuine Hunter replacement parts using the Parts Guide. Upgrade your fan with compatible accessories to enhance performance and style, ensuring optimal functionality.

Identifying and Ordering Replacement Parts

To maintain your Hunter ceiling fan’s performance, identify replacement parts using the Hunter Parts Guide. This guide helps determine the exact components needed, such as blades, downrods, or light kits. Refer to your fan’s model number, located in the manual or on the product, to ensure compatibility. Visit the official Hunter website or authorized retailers to place orders. For convenience, the website often features a “Parts” section with searchable databases. If unsure, contact Hunter’s customer support for assistance. Ensuring genuine parts are used guarantees safety and optimal functionality. Regularly check for upgrades to enhance your fan’s efficiency and style, and always follow the manual’s instructions for installation.

Upgrading Your Ceiling Fan

Upgrading your Hunter ceiling fan can enhance its functionality and aesthetics. Start by assessing your current fan’s features and identify desired upgrades, such as adding a light kit, installing a longer downrod, or integrating smart home compatibility. Visit the Hunter website or consult the Hunter Parts Guide to explore compatible upgrade options. Use your fan’s model number to ensure compatibility. Once selected, follow the detailed instructions in the instruction manual for installation. Upgrades may require basic tools and electrical knowledge. Always turn off power before starting. Regularly check for new upgrades to keep your fan modern and efficient. Contact Hunter support for assistance if needed.

Hunter Customer Support and Resources

Hunter Fan Company provides comprehensive support resources, including instruction manuals, troubleshooting guides, and contact options for assistance with installations, repairs, and upgrades.

Contacting Hunter Fan Company for Assistance

If you need help with your Hunter ceiling fan, contact their customer support team directly. Visit their official website for contact details, including phone numbers and email. You can also find troubleshooting guides and FAQs online. For specific inquiries, such as replacement parts or technical issues, use the resources provided on their website. Hunter Fan Company is committed to assisting you with installations, repairs, or upgrades. Ensure to have your fan model number ready for quicker assistance. Their support team is available to address your concerns and provide solutions to ensure your fan operates efficiently.

Additional Resources for Ceiling Fan Owners

Hunter Fan Company offers various resources to enhance your ceiling fan experience. Visit their official website for detailed manuals, troubleshooting guides, and installation videos. You can also explore their Parts Guide to identify and order replacement components. Additionally, Hunter provides FAQs and user forums where you can find answers to common questions. For visual learners, instructional videos on YouTube and their website demonstrate installation and maintenance processes. These resources ensure you can resolve issues independently and keep your fan running smoothly. Utilize these tools to maximize the lifespan and performance of your ceiling fan.