mary did you know sheet music pdf

Background of “Mary, Did You Know?”

“Mary, Did You Know?” is a beloved Christmas song written by Mark Lowry and Buddy Greene․ It reflects on the Virgin Mary’s perspective of her son Jesus’ divine purpose, blending spiritual depth with melodic beauty․

1․1 History of the Song

“Mary, Did You Know?” was written by Mark Lowry and Buddy Greene, originally performed for a church Christmas program․ The song explores the spiritual journey of Mary, reflecting on her son Jesus’ divine purpose․ Its lyrics blend theological depth with emotional resonance, making it a modern classic․ The song gained widespread popularity after being recorded by artists like Kenny Rogers and later by Pentatonix, whose a cappella version became a global hit․ The composition has since been arranged for various instruments and voices, making it a staple in Christmas repertoire․ Its enduring appeal lies in its ability to connect with listeners on both musical and spiritual levels, transcending generations and cultural boundaries․ The song’s history is a testament to the power of music to convey profound messages, ensuring its place in the hearts of millions worldwide․

1․2 Writers and Composers

The song “Mary, Did You Know?” was written by Mark Lowry, who penned the lyrics, and Buddy Greene, who composed the music․ Mark Lowry, a Christian singer, and songwriter, is known for his thoughtful and theologically rich lyrics, while Buddy Greene, a talented musician, brought the song to life with his haunting melody․ Their collaboration resulted in a piece that combines deep spiritual reflection with melodic beauty․ The song has since been arranged and performed by numerous artists, but the original composition remains a testament to the creative partnership of Lowry and Greene․ Their work has resonated with audiences worldwide, making “Mary, Did You Know?” a modern Christmas classic․ The song’s emotional and spiritual impact continues to inspire both performers and listeners, solidifying its place in Christian music history․

1․3 Popularity and Cultural Impact

“Mary, Did You Know?” has become a modern Christmas classic, widely performed and admired for its emotional and spiritual depth․ Its popularity soared with Pentatonix’s a cappella version, which showcased the song’s versatility and timeless appeal․ The song resonates deeply with both Christian and secular audiences, bridging cultural and musical boundaries․ Its thought-provoking lyrics and haunting melody have made it a staple in holiday playlists and church services alike․ The song’s ability to evoke reflection and wonder has contributed to its enduring popularity․ It has been covered by numerous artists, each bringing their unique interpretation, further expanding its reach․ The song’s impact is evident in its presence in various media, from concerts to recordings, solidifying its place in contemporary Christmas music․ Its influence continues to grow, inspiring new arrangements and performances, ensuring its legacy as a cherished holiday piece․

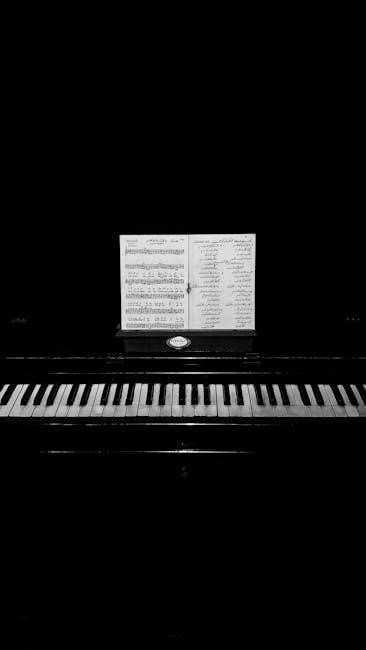

Sheet Music Specifications

The sheet music for “Mary, Did You Know?” is typically in D Minor, spanning 5 pages, and includes scoring for Piano, Vocal, and Guitar, making it accessible for various performances and arrangements․

2․1 Key and Number of Pages

The sheet music for “Mary, Did You Know?” is written in the key of D Minor, a choice that complements the song’s emotive and reflective nature․ Typically, the standard arrangement spans 5 pages, accommodating the melody, lyrics, and harmonic structure․ This length ensures that both the vocal and instrumental parts are clearly presented, making it accessible for performers․ The key of D Minor adds a solemn yet uplifting quality to the music, aligning with the song’s lyrical themes of divine purpose and wonder․ The 5-page format is concise yet comprehensive, providing all necessary details for pianists, vocalists, and guitarists to deliver a heartfelt performance․ This specification makes it ideal for both personal practice and professional arrangements, ensuring clarity and ease of use for musicians of various skill levels․

2․2 Scoring and Notations

The sheet music for “Mary, Did You Know?” is scored for Piano, Voice, and Guitar, with additional arrangements available for 58 other instruments․ It features 33 unique scorings and 4 distinct notations, ensuring versatility for various performances․ The notation is clear and precise, with chord symbols, lyrics, and dynamic markings provided to guide musicians․ This detailed scoring allows for seamless collaboration between vocalists and instrumentalists, making it suitable for both solo and ensemble performances․ The availability of multiple notations caters to different skill levels, from beginners to advanced players․ Whether for personal practice or professional arrangements, the sheet music’s comprehensive scoring and notation ensure a polished and emotive rendition of the song․ This attention to detail makes it a favorite among musicians seeking to capture the song’s spiritual and melodic essence․

2․3 Genres and Arrangements

“Mary, Did You Know?” is primarily classified under Christian and Christmas music genres, with its inspirational and spiritual themes resonating widely․ The sheet music is available in 16 distinct genres, catering to diverse musical preferences․ Arrangements range from simple piano and vocal duets to complex instrumental ensembles, ensuring versatility for performers․ The song is often performed in SATB (Soprano, Alto, Tenor, Bass) arrangements, making it ideal for choral groups․ Additionally, instrumental versions for piano, guitar, cello, and flute are popular, allowing soloists and ensembles to adapt the piece to their style․ The arrangements maintain the song’s emotional depth while offering creative freedom for interpretation․ This variety ensures that “Mary, Did You Know?” remains accessible to musicians of all levels and genres, from classical to contemporary․ Its adaptability has made it a staple in both religious and secular performances during the holiday season․

Instrumental Arrangements

“Mary, Did You Know?” offers versatile instrumental arrangements, including piano, guitar, cello, flute, and more․ Solo and ensemble options are available, providing flexibility for musicians to perform in various settings and styles․

3․1 Piano Arrangements

The piano arrangements of “Mary, Did You Know?” are widely popular, offering a rich harmonic structure that complements the song’s emotional depth․ The original key is D Minor, creating a hauntingly beautiful melody․ Sheet music for piano is available in various formats, including solo piano, piano-vocal, and SATB with piano accompaniment․ Many arrangements span 5 to 8 pages, depending on the complexity and inclusion of lyrics․ Scorings include piano, voice, and guitar, with 33 arrangements and 4 notations available across 16 genres․ The song’s versatility allows for transposition to suit different skill levels and preferences․ Whether performed as a solo or with a choir, the piano arrangement remains a cornerstone of this Christmas classic․ Its popularity has led to covers by artists like Pentatonix and Kenny Rogers, further cementing its place in holiday music repertoire․ The sheet music is easily accessible online, with both free and paid options available for download․

3․2 Guitar Arrangements

Guitar arrangements of “Mary, Did You Know?” are widely available, offering a beautiful accompaniment to the song’s emotional lyrics․ The original key in D Minor provides a rich harmonic foundation for guitar playing․ Sheet music for guitar includes chord charts, tablature, and standard notation, catering to both beginners and advanced players․ Many arrangements are paired with vocal lines, making them ideal for worship settings or personal performances․ The song’s melody translates well to acoustic guitar, with fingerpicking patterns enhancing its reflective tone․ Guitar arrangements are often included in the same PDF downloads as piano and vocal scores, with 33 scorings and 4 notations available across 16 genres․ Transpositions are also accessible, allowing guitarists to adjust the key to suit their vocal range or style․ Whether played as a solo instrument or part of an ensemble, the guitar arrangement brings a unique texture to this beloved Christmas song․

3․3 Vocal Arrangements

Vocal arrangements of “Mary, Did You Know?” are widely popular, offering a powerful way to express the song’s emotional and spiritual depth․ Sheet music for vocals is available in various formats, including SATB (Soprano, Alto, Tenor, Bass) arrangements, making it suitable for choirs and vocal ensembles․ The song’s melody is well-suited for both solo and group performances, with harmonies that enhance its lyrical richness․ Many vocal arrangements are paired with piano or guitar accompaniments, providing a lush backdrop for the vocals․ The song’s original key in D Minor complements vocal ranges, while transpositions are available to accommodate different voices․ Vocal sheet music is included in many PDF downloads, with 33 scorings and 4 notations across 16 genres․ This versatility makes it accessible to singers of all levels, from beginners to professionals․ The song’s emotional resonance and lyrical complexity make it a favorite for worship services, concerts, and holiday performances․

3․4 Instrumental Arrangements

Instrumental arrangements of “Mary, Did You Know?” are diverse and widely available, catering to various skill levels and preferences․ The song’s melody is beautifully suited for instruments like the piano, guitar, flute, and cello, with solo and ensemble arrangements offering rich musical expressions․ Many instrumental versions maintain the song’s original key in D Minor, while others provide transpositions to fit specific instrumental ranges․ Sheet music for instruments is often included in PDF and MIDI formats, allowing for easy download and performance․ Arrangements range from simple, heartfelt solos to intricate orchestral pieces, making the song accessible to both beginners and advanced musicians․ The emotional depth of the melody shines through in instrumental renditions, creating a powerful and moving experience․ Whether for personal practice or public performance, instrumental arrangements of “Mary, Did You Know?” provide a timeless and versatile way to enjoy this beloved Christmas song․

Downloading the Sheet Music

Download “Mary, Did You Know?” sheet music in PDF or MIDI formats․ Free options are available on platforms like Musicnotes, while paid versions offer additional features․ Visit PraiseCharts for various arrangements․

4․1 Free Download Options

Free sheet music for “Mary, Did You Know?” is available in PDF and MIDI formats․ Platforms like Musicnotes and PraiseCharts offer complimentary downloads, ideal for personal use․

These arrangements include piano, vocal, and guitar scores, perfect for beginners and experienced musicians alike․ Many websites provide access to chord charts and lyrics, ensuring versatility․

Some versions are simplified for easier learning, while others retain the original complexity․ Users can explore various transpositions to suit their vocal range or instrumental preferences․

The sheet music often includes lyrics by Mark Lowry and music by Buddy Greene, making it a great resource for worship or holiday performances․

Free downloads are a convenient way to access this beloved Christmas song, with options available for solo or group arrangements․ Always check licensing terms for usage rights․

4․2 Paid Download Options

Paid sheet music downloads for “Mary, Did You Know?” offer high-quality, professional arrangements․ Platforms like Musicnotes and PraiseCharts provide a wide range of options, including piano, vocal, and guitar scores․

These paid versions often include additional features such as chord charts, lyrics, and transpositions, catering to diverse musical needs․ Many arrangements are available in multiple keys, ensuring compatibility with various vocal ranges․

Paid downloads typically include rights for printing and performance, making them ideal for churches, schools, and professional performances․ Some platforms offer exclusive arrangements, such as those by Pentatonix or Tommee Profitt, adding unique twists to the classic song․

Purchasing sheet music supports the creators and ensures access to premium content․ With paid options, users can enjoy crystal-clear formatting and licensed use, perfect for both personal and public performances․

This option is recommended for those seeking professional-grade materials or specific arrangements not available for free․

Transposition and Customization

The sheet music for “Mary, Did You Know?” is available in multiple keys to accommodate different vocal ranges and instrumental preferences․ The original key is D Minor, but transpositions are offered to suit various performances․

Many platforms allow users to customize the sheet music by adjusting the key or selecting specific arrangements․ For instance, versions for piano, vocal, and guitar can be transposed to match the performer’s needs․

Some arrangements, like those by Pentatonix or Tommee Profitt, offer unique twists, blending contemporary styles with the classic melody․ These transposed versions are often available for instant download, ensuring flexibility for musicians․

Customization options also extend to scoring, with arrangements for solo instruments, ensembles, or full orchestras․ This adaptability makes the song accessible for a wide range of performances, from intimate solos to grand productions․

Whether for personal practice or professional performances, the ability to transpose and customize “Mary, Did You Know?” enhances its versatility, making it a timeless choice for musicians worldwide․

Performance Tips

Performing “Mary, Did You Know?” requires a balance of emotional depth and technical precision․ Start by connecting with the song’s spiritual message to convey its meaning authentically․

Dynamics are crucial; begin softly to build intensity as the song progresses, especially in the chorus․ Pay attention to tempo, maintaining a steady pace to support the melody’s flow․

For vocalists, focus on clear diction and expressive phrasing, particularly in the lyrical questions directed to Mary․ Pianists should emphasize the haunting melody in the verses while providing robust accompaniment in the chorus․

Guitarists can add texture with arpeggiated chords, while instrumentalists should balance their parts to avoid overpowering the vocals․ Practice the modulation sections thoroughly to ensure smooth transitions․

Consider adding subtle harmonies or instrumental solos to enhance the arrangement without distracting from the song’s core message․ Rehearse with a metronome to maintain consistency, especially in ensemble performances․

Finally, engage your audience by conveying the song’s wonder and reverence, making it a memorable experience for all․

Versions and Covers

“Mary, Did You Know?” has been covered by numerous artists, each bringing unique interpretations to the song․ Pentatonix’s a cappella version is particularly popular, showcasing intricate harmonies and vocal percussion․

Kenny Rogers recorded an early version, blending country elements with the song’s spiritual core․ Other notable covers include performances by Tommee Profitt featuring Jordan Smith, which add a contemporary, orchestral flair․

The song’s versatility is evident in its various arrangements, from intimate piano solos to grand instrumental ensembles․ Many artists have adapted it to fit their style, whether through gospel, pop, or classical interpretations․

Sheet music for these versions is widely available, catering to different skill levels and preferences․ This diversity highlights the song’s timeless appeal and its ability to resonate across genres and audiences․

Cultural and Musical Significance

“Mary, Did You Know?” holds profound cultural and musical significance as a modern Christmas classic․ Its thought-provoking lyrics, penned by Mark Lowry, explore the spiritual depth of Mary’s journey as the mother of Jesus․

The song’s melody, composed by Buddy Greene, complements its lyrical richness, creating a hauntingly beautiful tune that resonates emotionally with listeners․ Over the years, it has become a staple in Christmas playlists and church services worldwide․

Its ability to blend traditional and contemporary music styles has made it accessible to diverse audiences․ The song’s themes of faith, hope, and redemption continue to inspire, making it a timeless piece in Christian and holiday music․

Artists like Pentatonix and Kenny Rogers have further amplified its reach through their unique interpretations, ensuring its enduring legacy as a cherished holiday song․ Its impact extends beyond music, fostering reflection and connection during the Christmas season․